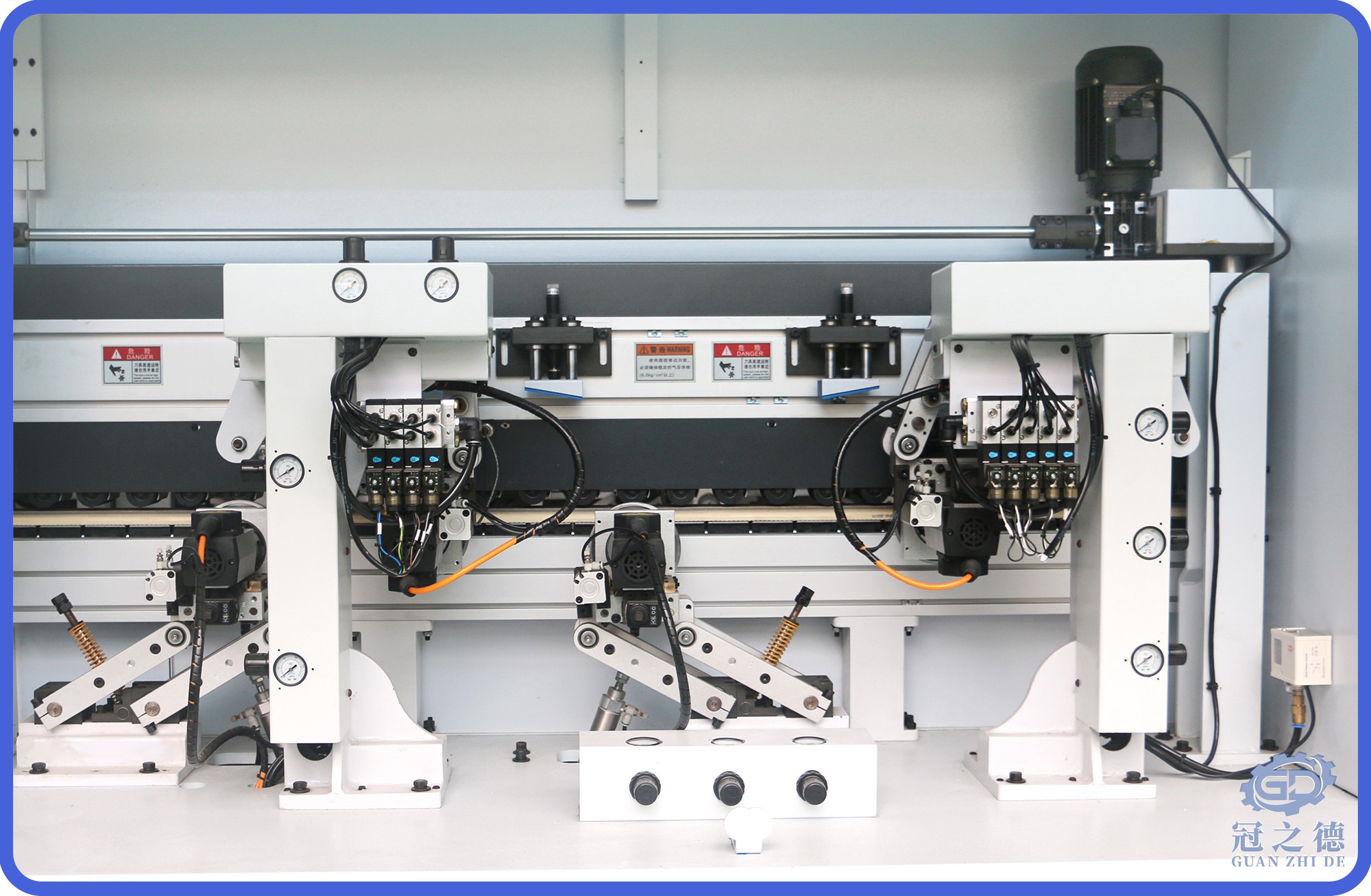

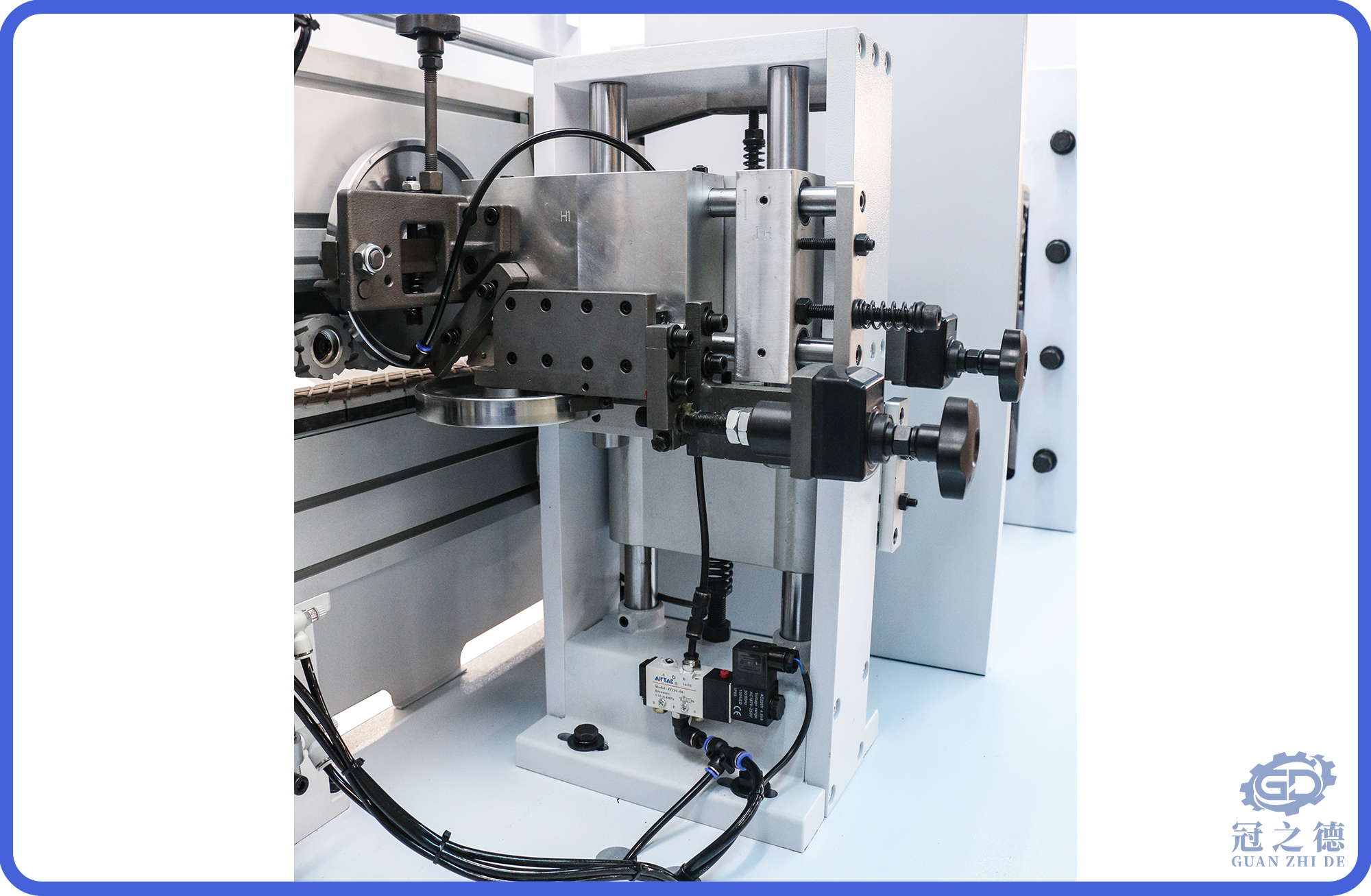

Aluminum alloy profile press beam, electronic height adjustment, asynchronous motor drive, mechanical digital positioning display.

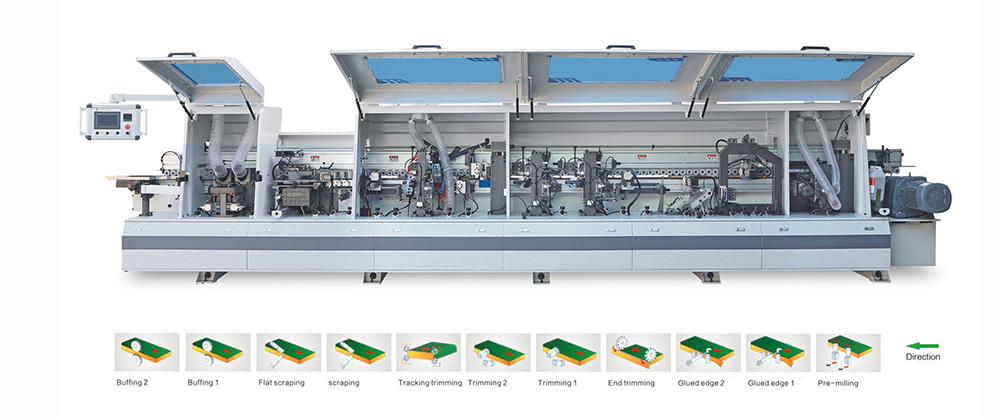

Feed Rate 12-23m/min Sheet Thickness 10-60mm Edge Thickness 0.4-3mm Sheet Width ≥80mm Track Trimmed Sheet Thickness 10-45mm Working Pressure 0.6MPa Totor Power 16.5KW Ocerall Size(lxwxh) 8100*1000*1600mm

| Product Description |

| Feed Rate | 12-23m/min | Working Pressure | 0.6MPa |

| Sheet Thickness | 10-60mm | Totor Power | 16.5KW |

| Edge Thickness | 0.4-3mm | Ocerall Size(lxwxh) | 8100*1000*1600mm |

| Sheet Width | ≥80mm | Net weight | 2800kg |

| Track Trimmed Sheet Thickness | 10-45mm | ||

| Product real shot and details |

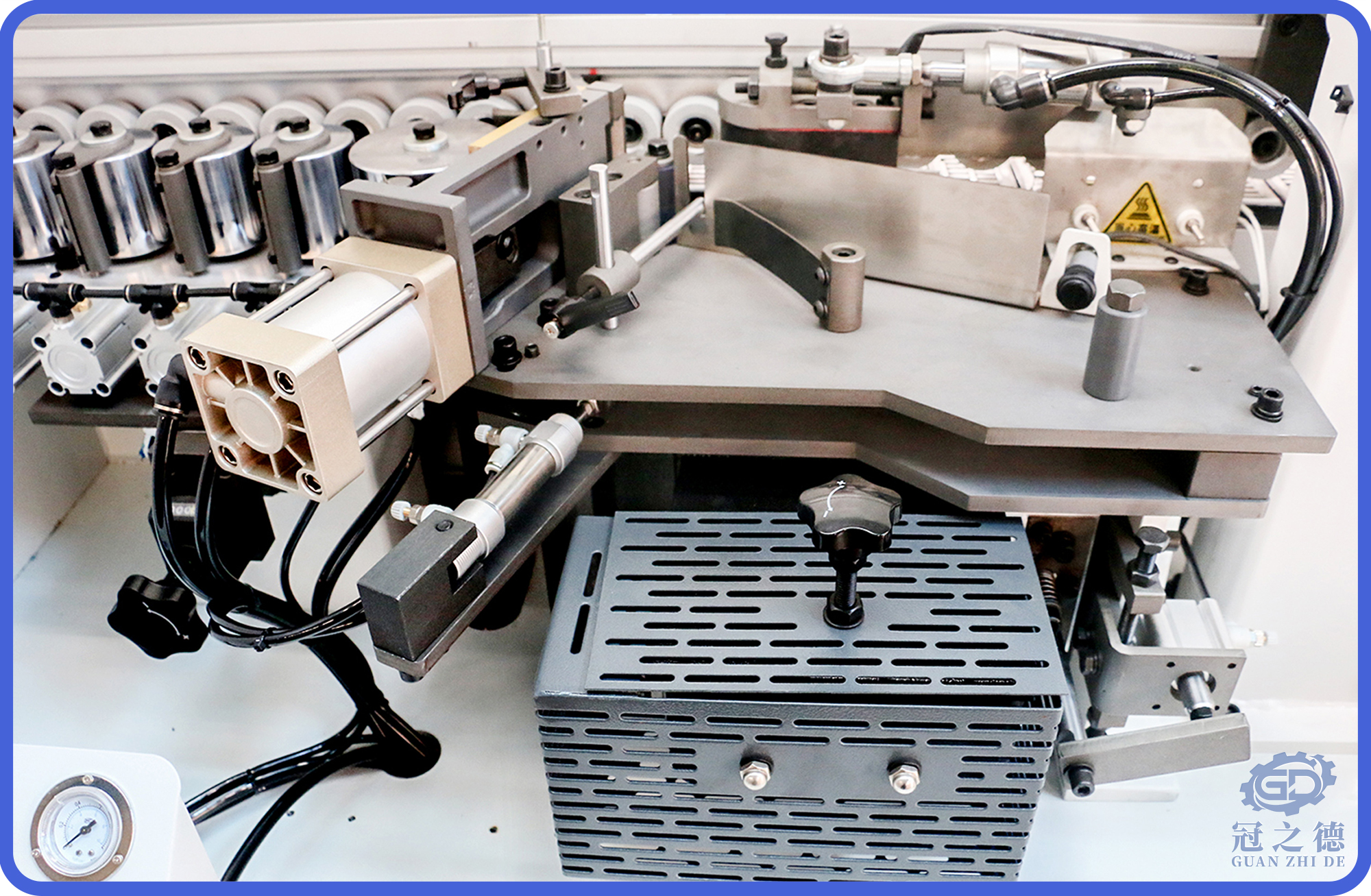

Aluminum alloy profile press beam, electronic height adjustment, asynchronous motor drive, mechanical digital positioning display.

To prevent adhesion between two identical or different plates

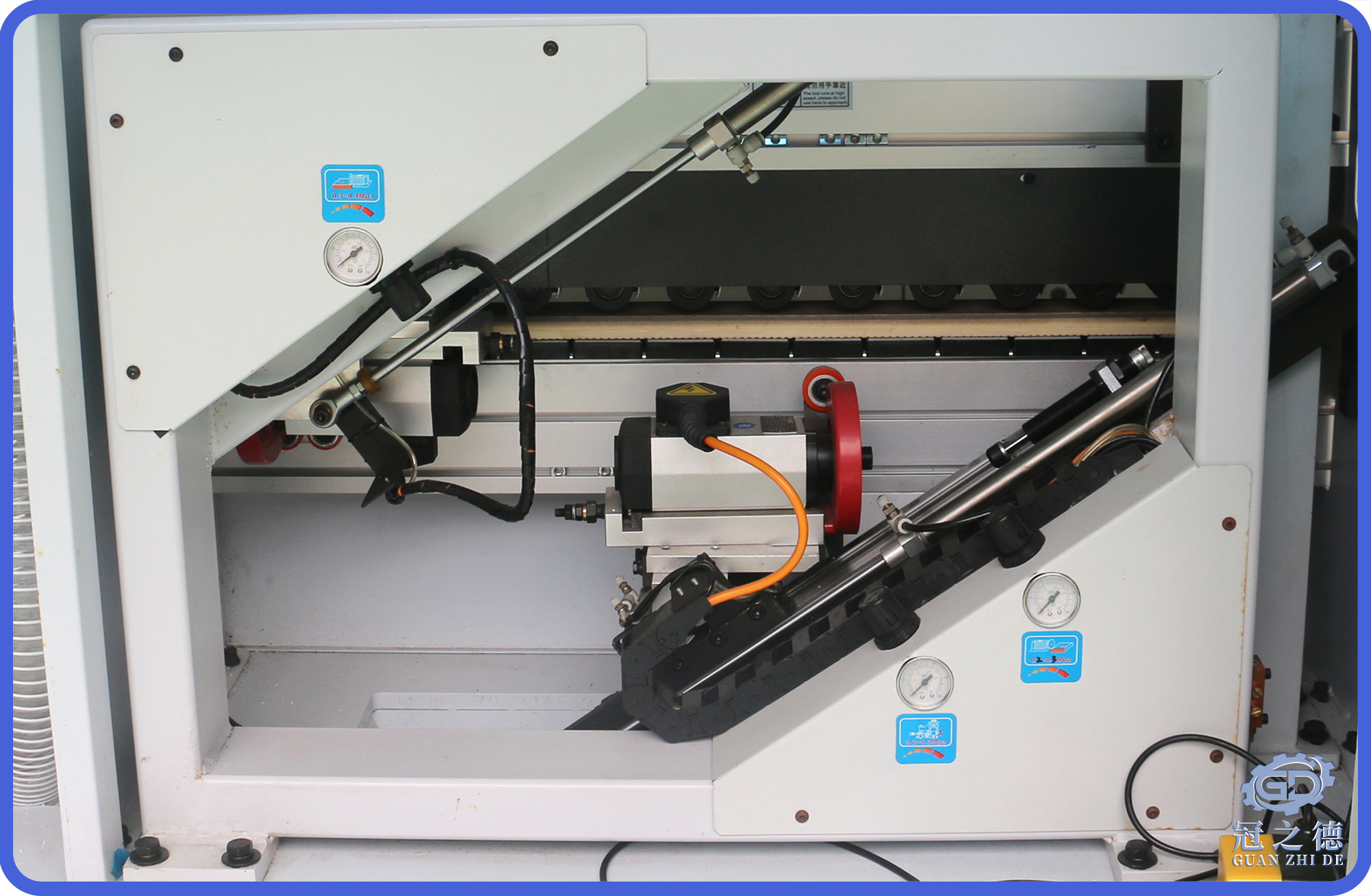

Pneumatic front and rear feed, dual independent milling thickness adjustment function, with independent backup gear, standard equipped with 2 * 2.2KW high-frequency high-speed motor up to 12000 rpm

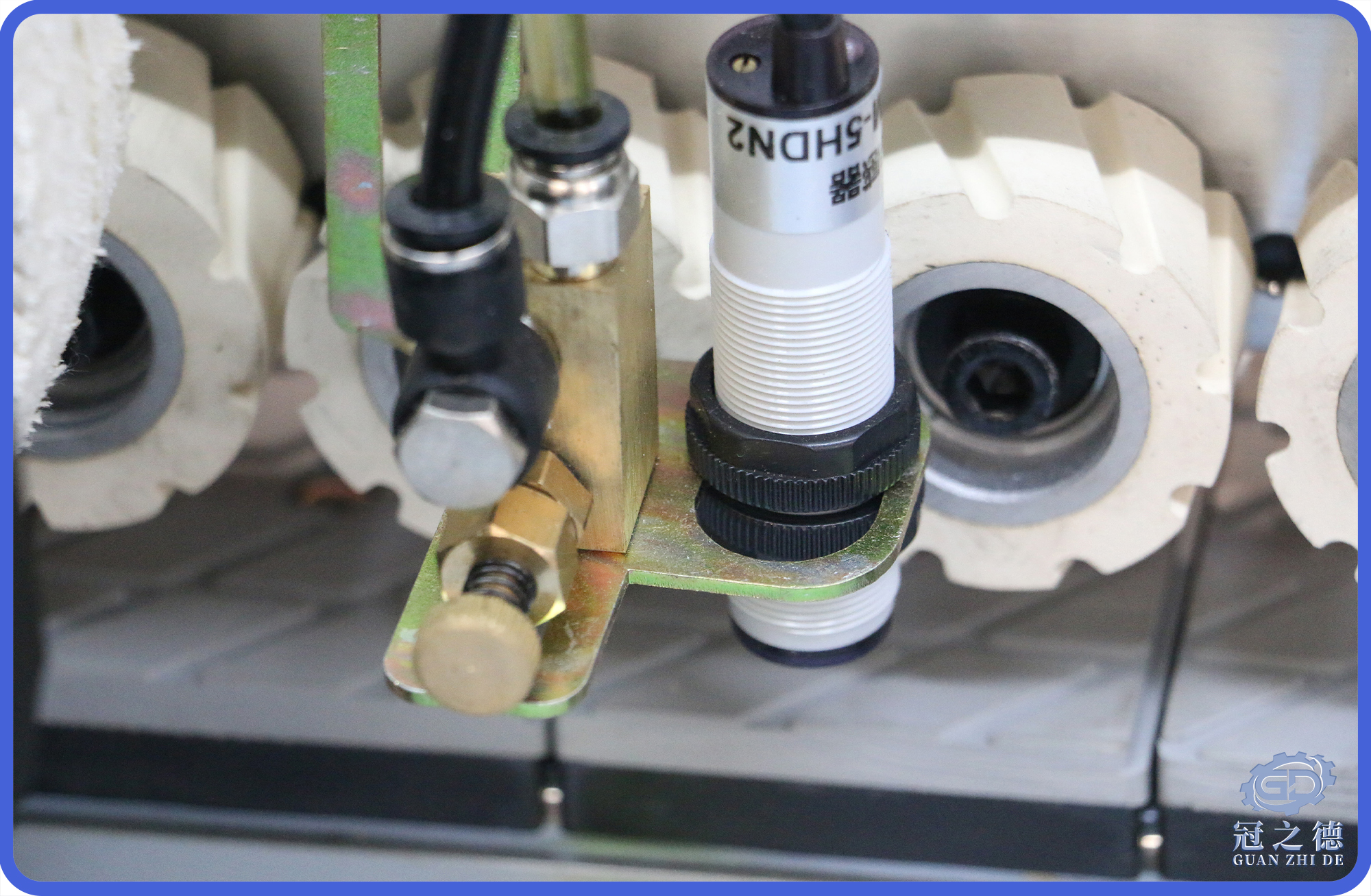

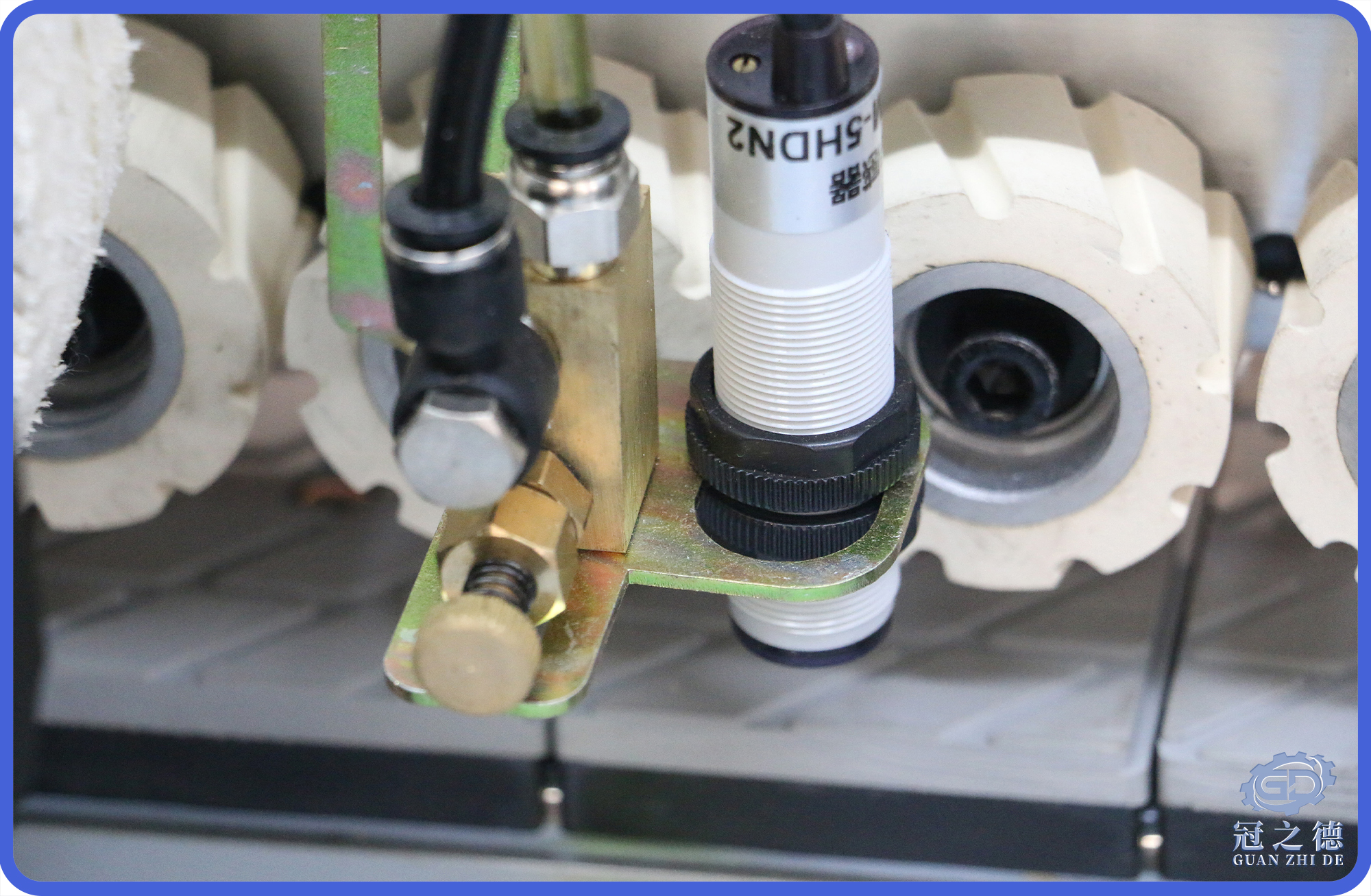

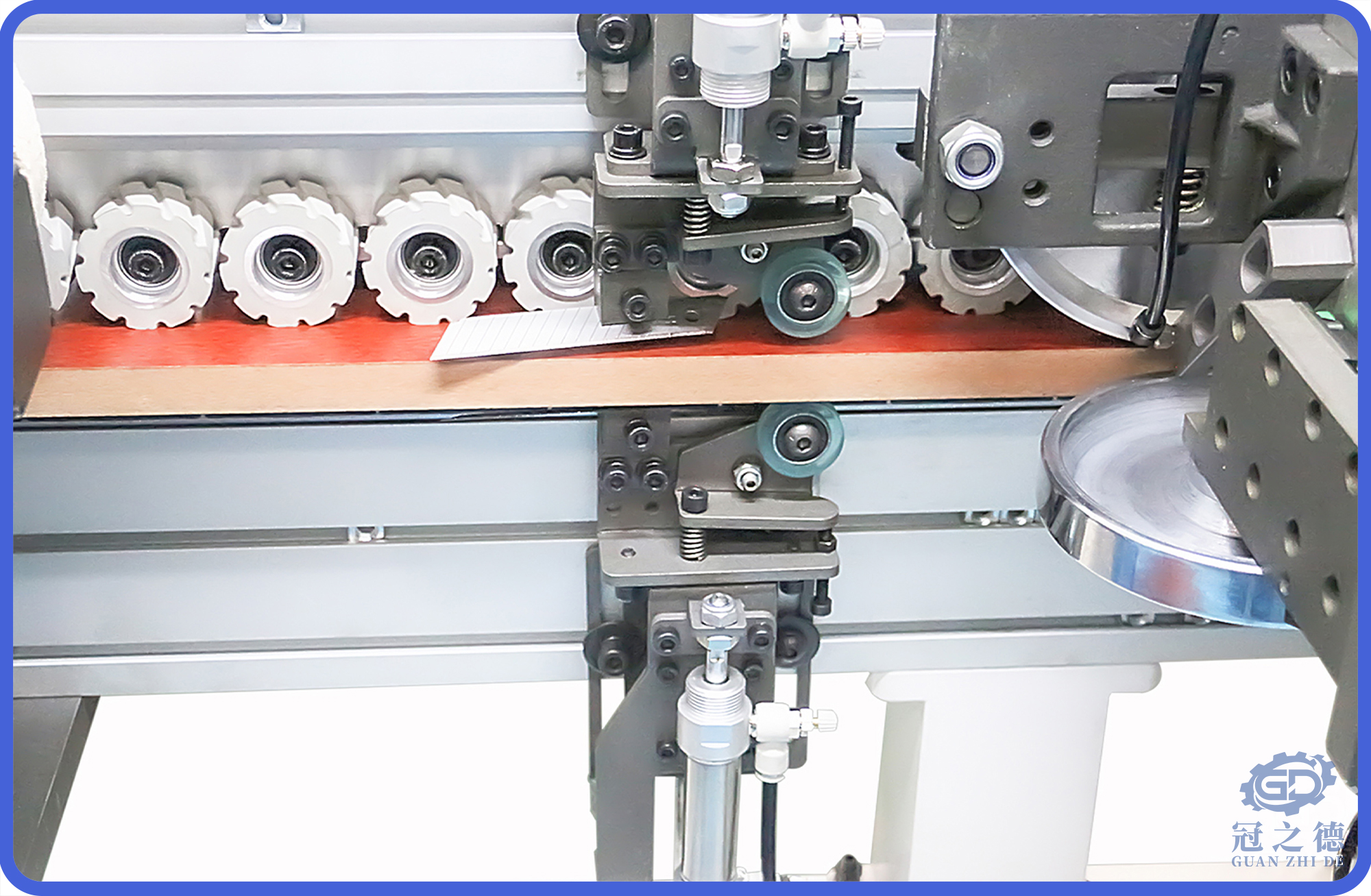

One main wheel, with a diameter of 100mm, and five driven wheels at the rear, to ensure a firm fit between the edge banding belt and the plate

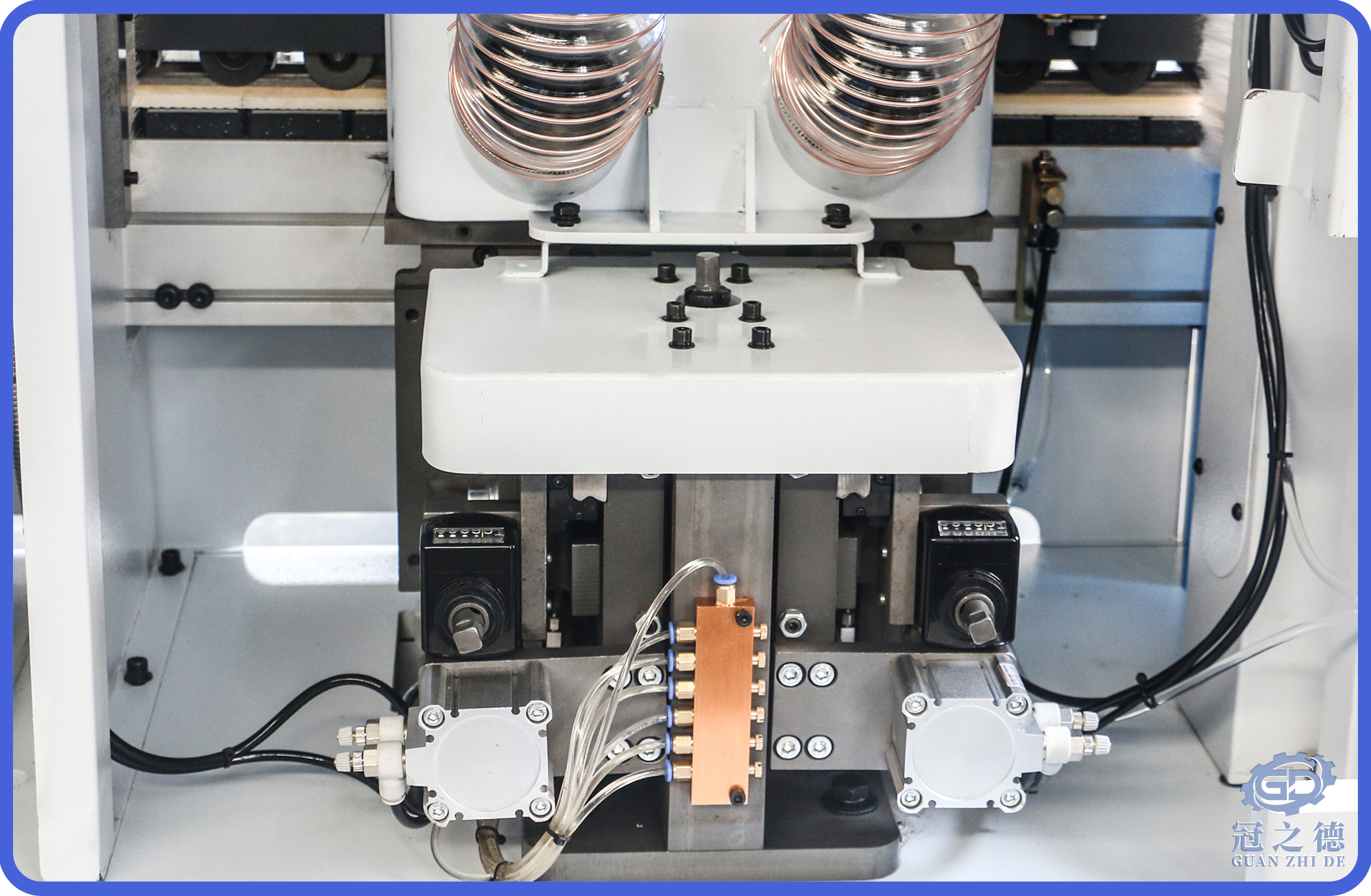

Fully sealed and self-cleaning PUR edge sealing and gluing device. This model adopts a no glue box design, which eliminates the trouble of cleaning the traditional glue pot, reduces the frequency of operation, and improves production efficiency. It uses infrared induction to control the glue amount, and the entire process of glue supply is sealed without residue.

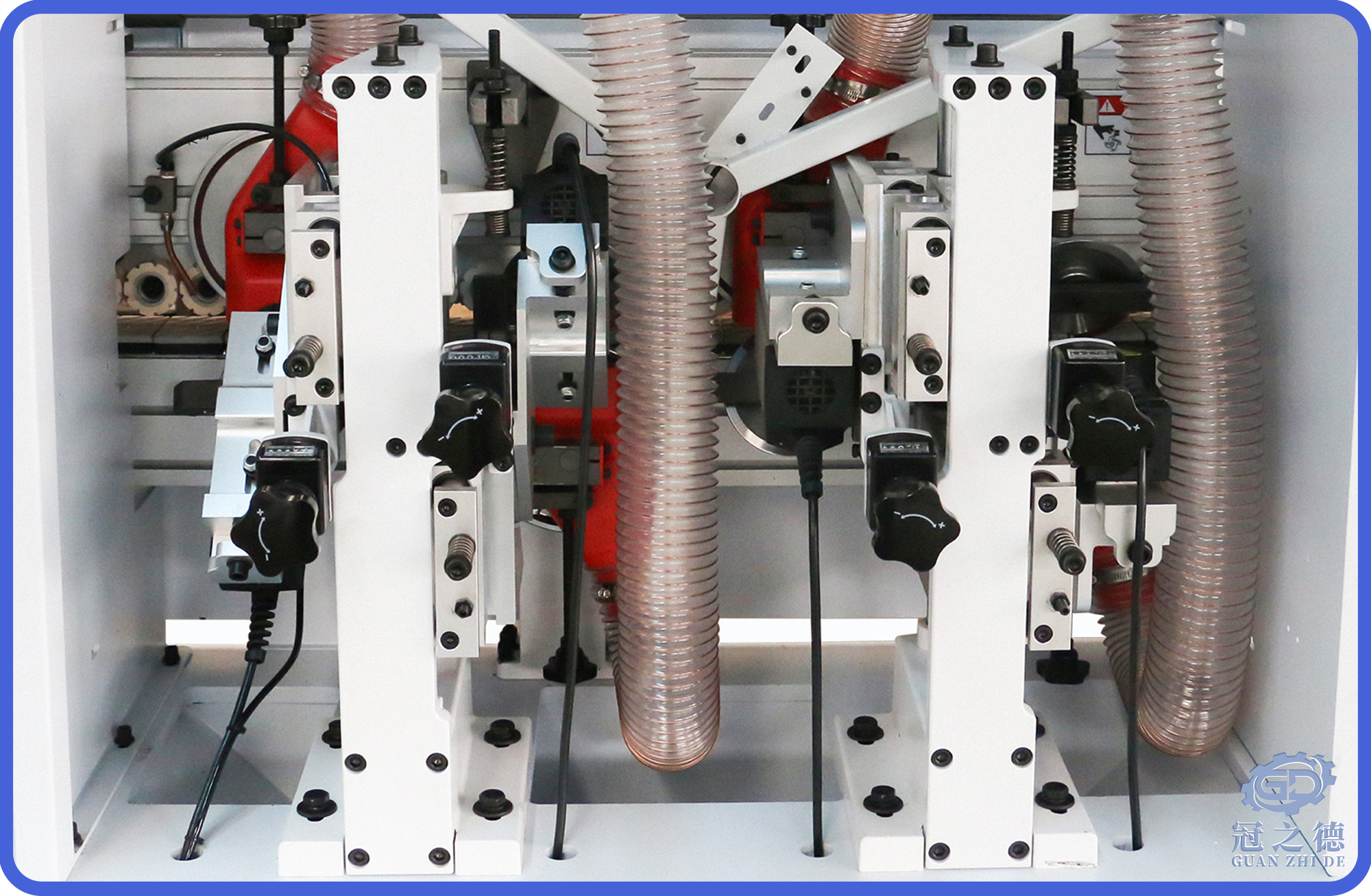

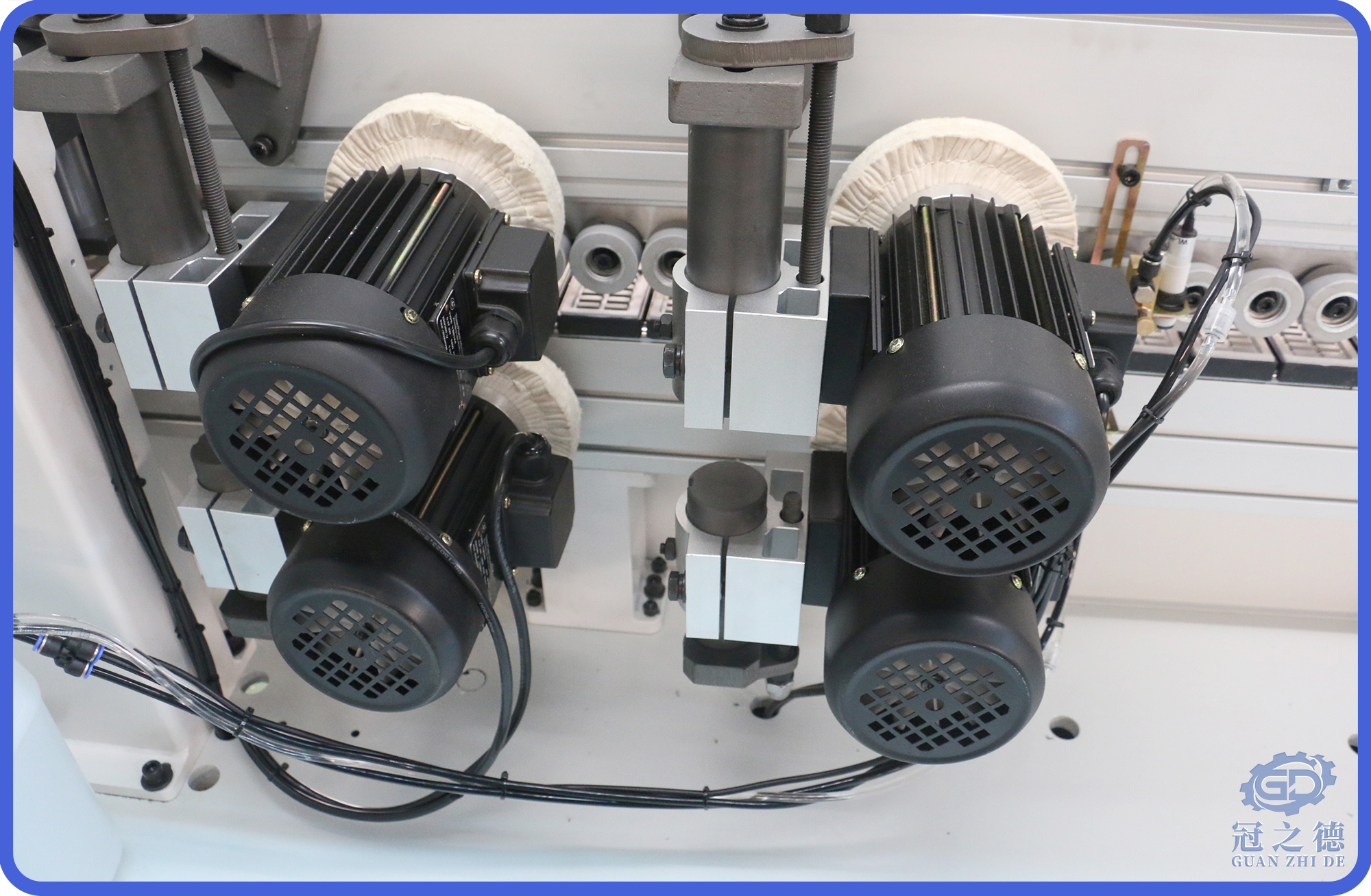

Two motors, each with a power of 0.37KW, a frequency of 200hz, and a rotational speed of 12000 rpm/minAdopt a unique working air pressure and start-up lifting air pressure separation mode to ensure the stability of head trimming

During edge banding, the high-frequency high-speed motor structure is used to trim the excess edge banding strips on the edge banding plate, so that the width of the edge banding strip is consistent with the width of the edge banding plate, and the motor angle is adjusted;Equipped with independent vacuum hood.Two motors each with a power of 0.75k

The four corners of the edge banding belt bonded to the plate are milled into an R-arc shape using a profiling wheel movable left and right profiling rounding device.

The trimming knives on both sides of the plate scrape away the wavy knife marks caused by the trimming knife on the edge banding belt, making the size of the modified R angle the same as that of the finely trimmed R angle. Make the upper and lower parts of the plate more smooth and tidy.

Remove excess hot melt adhesive from the workpiece plate surface

Used for polishing the longitudinal edge of the workpiece;Clean the edges of the workpiece and remove excess glue.

Contact: melody

Phone: 13724936060

Tel: +86-13724936060

Email: melody@zhongercnc.com

Add: Room 509,Building 3, Shurheli Scienoe and Technology Innovation Park,No. 2. Zhenhua West Road, Licun, Lunjiao Street, Shunde District, Foshan City

We chat