X-axis travel 4600mm Y-axis travel 1800mm Z-axis travel 250mm Proce ssing wood length 70-3050mm Proce ssing wood width 30-1200mm Proce ssing wood thickness 10-60mm

| Product Description |

| Technical Data |

| X-axis travel | 4600mm | Drill group power | 2.2kw×2 |

| Y-axis travel | 1800mm | Lou milling spindle mode | Er3 |

| Z-axis travel | 250mm | Lou milling speed | 18000r/min |

| Processing wood length | 70-3050mm | Lou milling spindle power | 3.5kw×2 |

| Processing wood width | 30-1200mm | Workbench height | 900mm |

| Processing wood thickness | 10-60mm | Lord enters the diameter of the suction pipe | 150mm |

| X-axis max. moving speed | 150m/min | Total power | 18.7kw |

| Y-axis max. moving speed | 75m/min | Operating voltage | 380V 50HZ |

| Z-axis max. moving speed | 30m/min | Working pressure | 0.6-0.8Mpa |

| Drill group vertical drilling | 5+4 | Weight | 3800kg |

| Drilling group horizontal drilling | Y2×2, X2×2 | Dimensions | 5500×2750×2300mm |

| Drill down vertically | 9 支 |

| Product real shot and details |

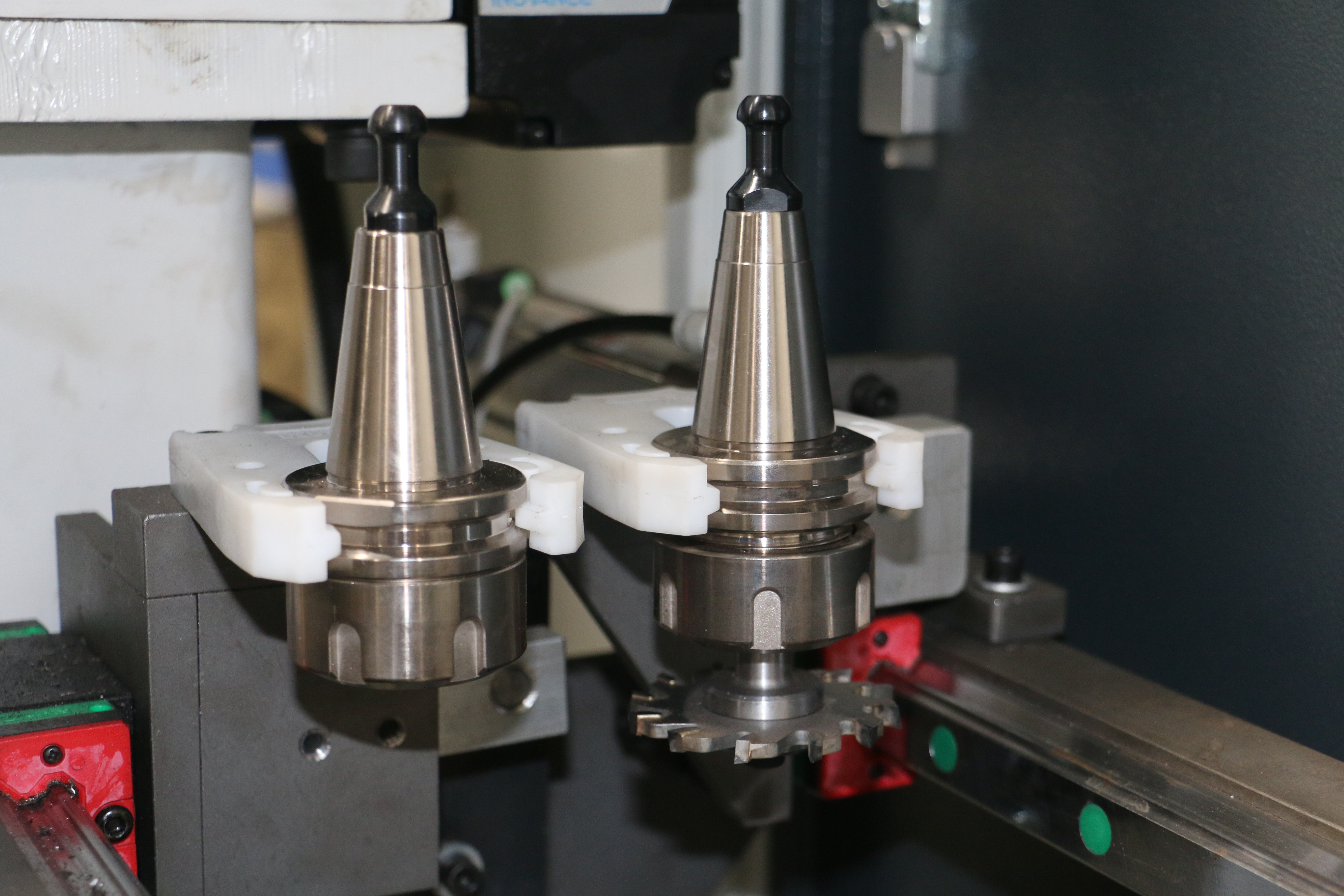

Pressure wheel integrated drilling package

Pressure wheel integrated drilling package

High precision drilling package, efficient drilling, and the drilling package comes with a pressure wheel pressure plate to keep the plate straight for processing

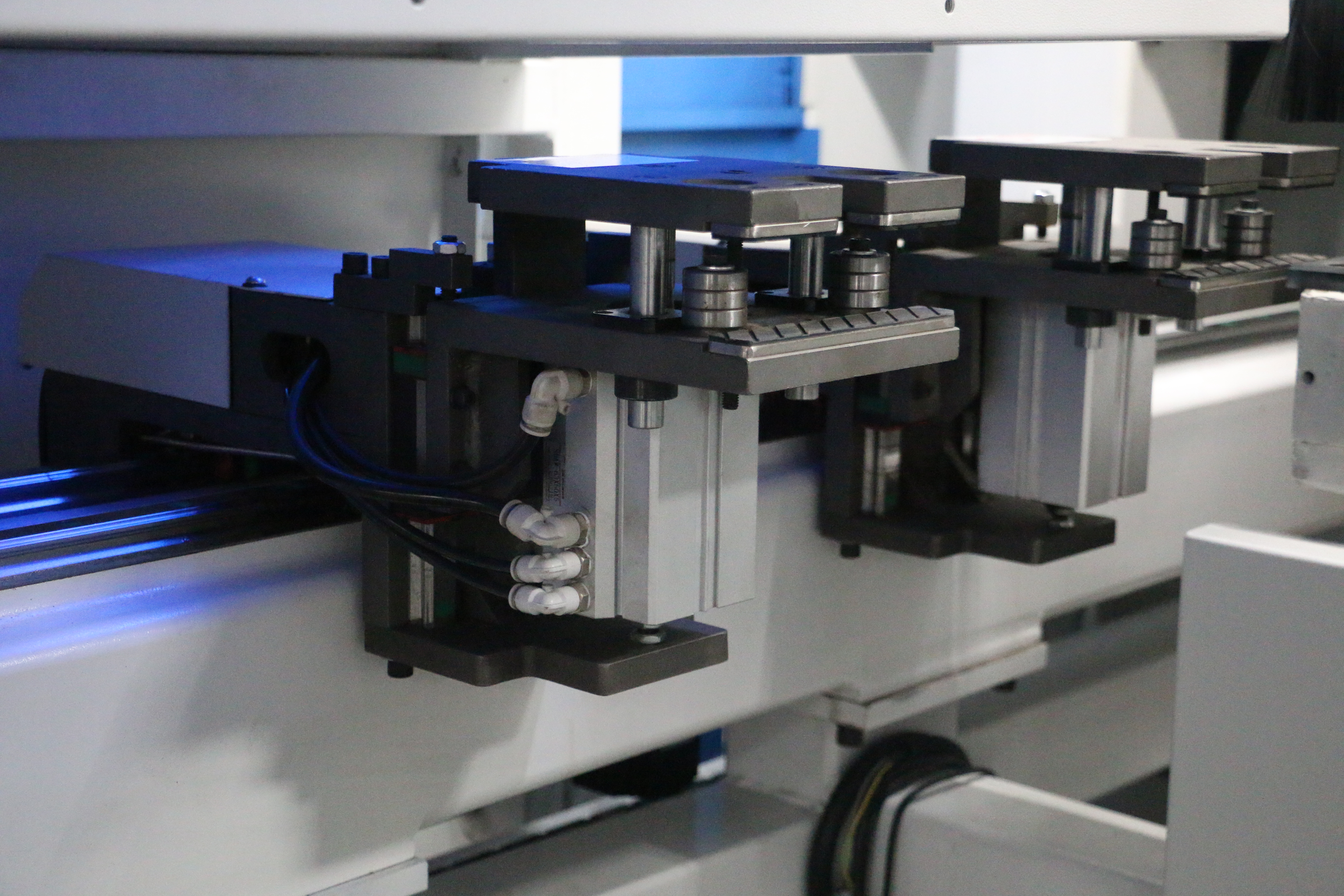

Straight automatic tool magazine

Straight automatic tool magazine

Automatic tool change in the straight line tool library, continuous and efficient processing, meeting various processing needs

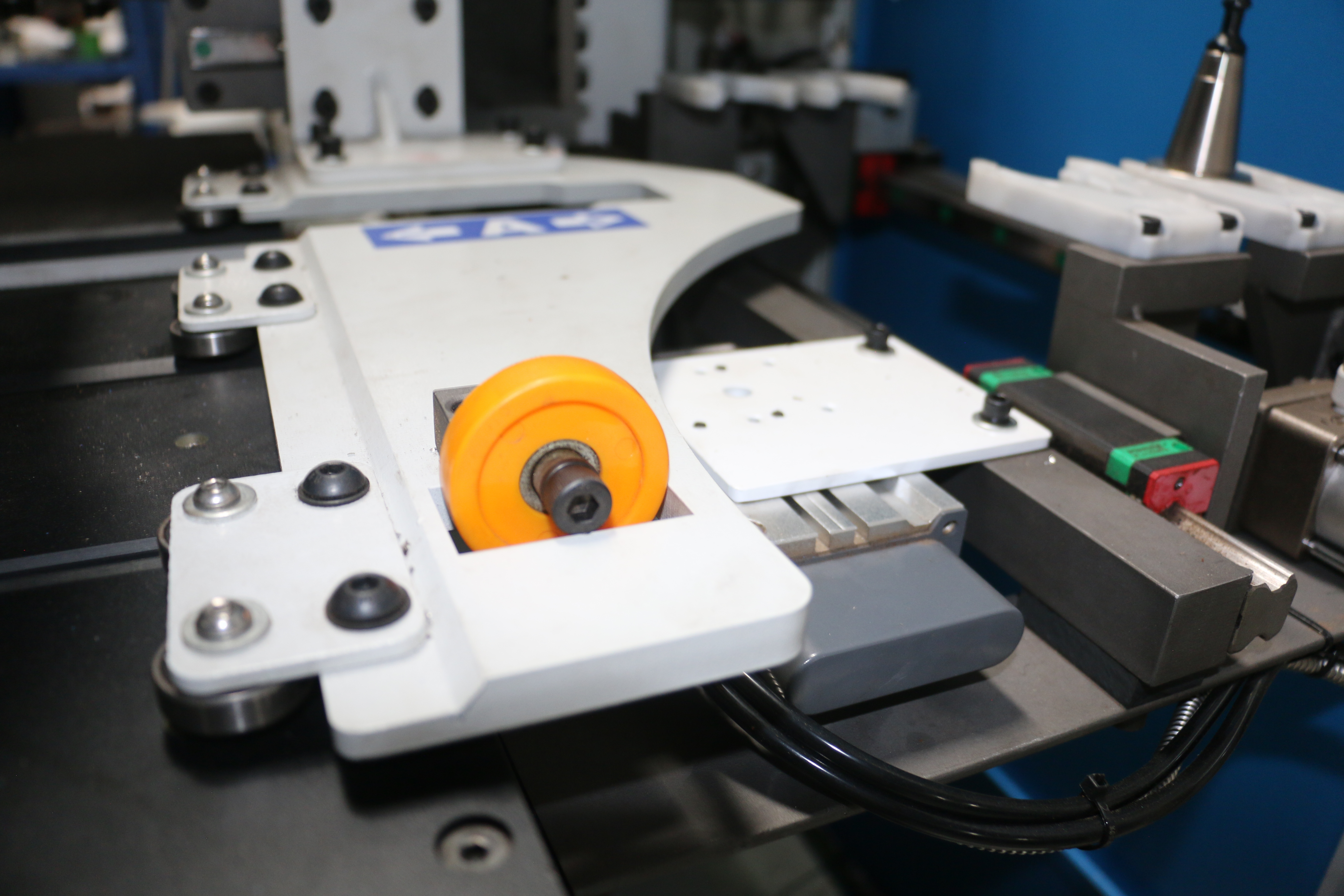

Pioneering C-type double gripper

Adopting a C-shaped groove double clamp mobile phone structure, the gripper will lift and hang in the air during the movement of the clamp plate. The plate should be kept at a certain distance above the processing table to avoid damage to the plate surface caused by collision between the plate and the table

Backing plate and material

Two point matching with material support ensures even force on the edge of the plate without deviation. The support plate is positioned with a clamp, making it more stable during processing

Color screen control display

Color screen control display

Single arm suspension is easy to operate, saves space, operates safely and reliably, has a simple and friendly interface, and has complete operation prompts and troubleshooting guidelines

Contact: melody

Phone: 13724936060

Tel: +86-13724936060

Email: melody@zhongercnc.com

Add: Room 509,Building 3, Shurheli Scienoe and Technology Innovation Park,No. 2. Zhenhua West Road, Licun, Lunjiao Street, Shunde District, Foshan City

We chat